|

|

|

|

|

Home > PRODUCTST |

|

|

Atactic Polypropylene (APP) |

|

|

|

|

| |

|

| |

Type Type |

APP BLOCK:Viscosity at 200°C: 500000cPs ~ 1500000cPs

Volatiles: 3% |

|

APP PELLET APP PELLET |

Viscosity at 200°C: 300cPs ~ 5000cPs

Volatiles: 3% |

|

Characteristics of Quality Characteristics of Quality |

1.Tight specification is strictly controlled through refining process.

2.High compatibility with other chemicals |

|

Recommended Uses Recommended Uses

|

10 months @25°C1.As base polymer for hot melt sealing(for building, car, household electric apparatus)

2.As filling-up agents for cable or capacitor

3.As quality improving agents for polypropylene polymer

4.As master-batch base polymer for calcium carbonate |

|

|

|

|

Alphaolefin Copolymers (Elastomer) in Off Grade

|

|

|

|

|

Anti-abrasion Masterbatch VS-550

|

|

|

VS-550 is an anti-abrasion masterbatch, contain ultra high molecular weight siloxane polymers. It can provide significantly improved surface properties, including better lubricity and abrasion resistance especially. It will not affect the original properties of plastic and rubber, such as light resistance, weather resistance. VS-550 can be used in TPR and PCU (PVC Physical Foaming). Adding 2 phr of VS-550 will enhance the value of abrasion (AKRON and NBS) from 15 to 30%.

|

|

Suggested Usage Suggested Usage

|

- Dosage: 1~2 phr

- VS-550 can be use with TPR for injection directly. However, it will get better effect for injection after compounding through extruder.

- 1.Suggested Formula: TPE 475: 60/ PS: 20/ EVA: 3/ HDPE: 3/ Light CaCO3: 20/ Stearic Acid: 0.

|

|

Performance in application Performance in application

|

| |

Specific gravity |

AKRON abrasion

mm3 |

NBS abrasion

% |

| TPR |

0.95~1 |

0.33~0.36 |

45-55 |

| TPR/VS-550(2%) |

0.95~1 |

0.22~0.25 |

60~75 |

| PCU |

0.65~0.75 |

|

35~45 |

| PCU/VS-550(2%) |

0.65~0.75 |

|

60~65 |

|

|

|

Environmental Friendly Water-Borne Heat Insulation Paint HIP-966

|

|

|

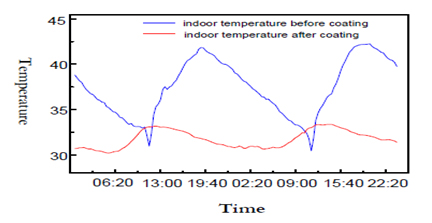

Product Introduction Product Introduction |

HIP-966 is an environmental friendly type polymer consisted of numerous micron-scale vacuum ceramic particles. Not only does it have the properties such as lightweight, excellent heat isolation, weather durability and good adhesion, but also even conserves heat, isolates sound, and forms a waterproof protective layer. Reflection rate highly increases 96% after with the HIP-966, i.e. the absorbance rate of short wavelengths is greatly reduced which largely reduces heat absorption of a building’s outer shell of a building and helps heat dissipation via radiation.

|

|

Purposes Purposes

|

HIP-966 is suitable for buildings of outdoor roofs, RC structures, motel businesses, shopping markets, iron shacks, concrete walls, corrugated sheets, asbestos tiles, cargo houses, grain-houses, gas storage tanks, cold water piping, poultry farm, wall faces, wooden houses etc. for specialized waterproofing and heat insulation, and all are shown with apparent temperature decrease.

|

|

Characteristics: Characteristics: |

- Constant temperature heat insulation:

The surface temperature of corrugated sheets on a RC building roof is reduced approximately 15~20°C under sunshine exposure, which can reduce the indoor temperature 6~12°C.

- Excellent extension property:

Does not crack easily and has good tension; will not crack and fall off due to distortion of the iron sheet.

- Waterproof:

HIP-966 can block water drops; possesses excellent waterproofing.

- Iron sheet anti-rust:

The roof of iron shacks will easily rust, but with the waterproofing of HIP-966, the iron sheet is protected from rust. This enables usage of the iron sheet to increase several of years.

- Environmental friendly:

Does not contain hazardous heavy metals and formaldehyde; the pH value of HIP-966 is 8.5 (weak alkalinity, does not easily grow bacteria). It is a non-toxic environmental friendly material.

|

|

|

|

|